Can I Install Rooflights Myself?

23rd September 2024

Adding a rooflight to your home can unlock its potential through increased natural daylight and ventilation and you can install a rooflight yourself, however, it requires extensive prior planning to ensure a seamless installation, with everyone on site remaining safe.

Choosing The Right Rooflight

Choosing the perfect rooflight for your home will depend on your unique requirements; do you require increased ventilation? Or are you looking to access your roof for maintenance?

There are various factors that affect the type of rooflight that you will purchase; from the size of the room to the glazing material that you desire.

For more guidance on selecting the right rooflight for your requirements, please read our comprehensive ‘How To Pick Rooflights’ blog.

Make Safety A Priority

When installing a rooflight, you need to ensure that the safety of everyone on site is of utmost priority, installing a rooflight will involve working at height therefore precautions need to be taken to ensure safety.

First, you need to assess if the site area is actually suitable for an installation, if the area is constricted and suitable access is not possible, you should strongly consider installing the rooflight on a more accessible area of the roof. If this is not feasible, you should contact an experienced contractor who will have access to the necessary equipment to reach the area such as cherry-pickers and scaffolding.

Prior to commencing the rooflight installation, you need to undertake a comprehensive risk assessment to identify all potential risks and take steps to mitigate these risks. Potential risks that could be identified include manual handling and fall from heights. Many risks are not able to be completely eradicated, but you can take steps to mitigate the risk.For example, the risk of manual handling can be reduced through the use of mechanical lifting equipment, the use of the equipment reduces the need for people on site to manually lift the rooflight as this could lead to injury.

Care should be taken at all times when on site to ensure the health and safety of all people present, and site housekeeping on the day is important; cleaning up any spills when they occur, wearing the correct PPE (Personal Protective Equipment) and halting works if weather conditions become too volatile.

Understand Building Regulations

Before commencing the installation of your rooflight, you should ensure that you have read and understand the relevant Building Regulations (Building Regulations will differ whether you live in England, Scotland or Wales)

Adhering to Building Regulations is a legal requirement as they are in place to ensure the health and safety of people in and around all types of buildings (residential, public and commercial).

Adding a rooflight to your home will require your roof to be changed significantly to accommodate the extra weight that the product introduces, and your chosen rooflight needs to provide sufficient insulation against heat loss once installed.It is also important that you apply for planning permission, should you need to. Planning permission is not commonly required for rooflight installation as it falls under “permitted development” however you are required to apply for planning permission if you live in a conservation area or if your desired rooflight is going to protrude more than 150mm above the existing roofline.

Gather Necessary Tools & Materials

Before undertaking your rooflight installation, ensure that you have all required tools and materials prepared on site. Common tools used for a rooflight installation include a drill, screwdriver, tape measure, and sealant/roofing adhesive. You should check the manufacturer’s installation instructions to see if there are any specific tools or materials required for installation.

Prior to commencing the rooflight installation, you should inspect your rooflight for any damage obtained in transit. If you detect any damage, you need to inform the rooflight manufacturer as soon as possible so a replacement product can be arranged. Many manufacturers have a set time period in which they need to be notified of any damage, if you surpass this date, your product may not be eligible for a return or refund.

Prepare The Roof Opening

Before constructing your upstand and preparing the surrounding area for installation, you first need to assess the structural integrity of the roof; is it strong enough to carry the additional weight of a rooflight? If your roof is deemed unsuitable in its current state, you can take measures to reinforce the framework such as adding additional wooden framing to boost the roof’s structural integrity.

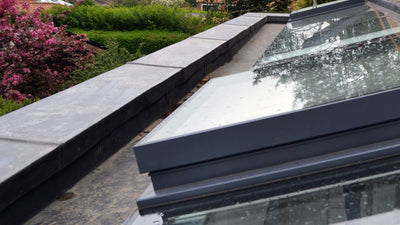

You will also need to address any existing cracks or leaks prior to installation as this will compromise the water tightness of your new rooflight.Most rooflights on the market are specially designed to be installed on a pre-built upstand, these are normally constructed by experienced builders prior to the day of installation. Different rooflights will have differing upstand requirements therefore it is important to read your manufacturer’s documentation to ensure that your upstand is constructed correctly.Thoroughly reading your documentation is crucial as rooflight manufacturers may opt to reference varying ‘critical dimensions’. For example our Flushglaze Flat Rooflight is specified using the External Weathered Kerb dimension, therefore this dimension is the dimension that you should have your upstand constructed to. However, rooflights can sometimes be specified by the critical dimensions of Internal Viewable or Structural Opening, you should always check your dimensions with your manufacturer to mitigate expensive, last minute changes on site.

When installing your rooflight, it is important to ensure that the roof is clear of any debris or instructions as this will hinder the installation process and it may also compromise the water and weather-tightness of the product, which could lead to costly repairs in the future.

Install Your Rooflight

When you are ready to install your rooflight, after addressing any risks present on site and inspecting your rooflight for any damage, you should enlist the assistance of mechanical lifting equipment to lift your product onto the roof and carefully maneuver it into place, manually handling a rooflight is not recommended due to the risk of injury.

During installation, you need to closely follow the installation instructions provided to you by your rooflight manufacturer as not adhering to these could lead to a faulty installation. Not adhering to the instructions set out by the manufacturer could also void your product warranty.Your instructions will also outline any specialist tools or materials required to install the product, so you should ensure that you read all documentation prior to commencing the installation on site. Different types of rooflights will have varying installation procedures, for example, opening rooflights are more complex to install than fixed rooflights as there are complex electrics involved. Whilst it is not a legal requirement to have your opening rooflight wiring completed by a qualified electrician, we strongly urge you to enlist their services as this will achieve the optimal installation result and reduce the risk of electrocution for those not acquainted with working with electricity.

Test For Functionality

Once your rooflight has been successfully installed, you need to inspect the product and surrounding roofing to ensure that there are no gaps or leaks as this will compromise your installation, leading to costly damage in the future.

If you have installed an opening rooflight, you need to test all mechanisms to ensure that they are operating how they should. If any issues arise, address these promptly, and if you are unsure, refer to your manufacturer’s instructions or contact them for assistance.

Enjoy Your Rooflight

Now that you have installed your rooflight, adhering to health and safety guidelines and Building Regulations, you can enjoy the numerous benefits that rooflights offer such as increased natural daylight and improved levels of ventilation.

All reputable and trustworthy rooflight manufacturers will offer a period of product warranty on their rooflights, therefore you can enjoy your rooflight for years to come.So, the answer is yes, you can install rooflights yourself however we urge you to thoroughly consider factors such as site access, health and safety of site members and the use of mechanical lifting equipment. The health and safety of site members needs to be your top priority.rooflights.com has been supplying the UK’s builders with high quality rooflights and roof windows for a decade, reach out to our experienced team today to discuss your requirements and get the answers to your rooflight/roof window questions.

Read more

DIY

installation

Rooflight

What To Consider When Building An Extension

23rd September 2024

You have decided that you want to construct an extension on your home, but where do you start? With so many intricacies when building an extension, it can be overwhelming when starting your project.

Whether you are expanding your living space or adding a new office, incorporating rooflights can transform your home through increased levels of natural daylight.

Read this blog to understand everything that you need to consider prior to building your home extension.

With the mantra of “Don't move, improve” ever-increasing in popularity, many people are opting to build an extension to meet their updated requirements rather than moving to another home. This is because extensions are completely flexible in terms of their applications; they can be used to facilitate extra bedrooms for a growing family or they can host a “home office” for people working remotely.

With the large expenses associated with moving house, such as legal costs and stamp duty, it is no surprise that more people are choosing to build extensions.

What Are Your Requirements?

Building an extension can turn your current home into your dream home, and identifying why you require an extension will allow you to correctly design and budget your project.

The main benefit of constructing a home extension is the complete flexibility; you are able to tailor the extension to your unique requirements. Some projects will require a larger budget than others, for example implementing an ensuite bedroom may incur more costs than a simple, home office, therefore you need to factor in all of your requirements when budgeting your extension project.

Is The Project Viable?

Following on from our last point, you need to assess numerous factors such as budget before planning your extension project.

The first factor to consider is the timeline, depending on the desired application of the extension, construction timelines can vary greatly. You need to decide how long you are comfortable with building works taking place at your property as this will dictate how much can be achieved in your desired timeframe.

The next factor to consider is the suitability for you and your family whilst the building works are taking place; many families opt to move out whilst the works are taking place due to the disruption, lack of water and electricity, and noise occurring throughout works.

You will need to factor the cost of rent into your budget, if your budget does not facilitate this additional cost you could consider staying with friends or family or remaining in the property in selected rooms, your builder will be able to inform you of any water/electricity outages for forward planning.

Similarly, you should carefully consolidate your budget to ensure that your project does not over run your funds. Building an extension can incur numerous costs such as professional fees, materials, and more.

It is important to note that you need to inform your home insurance company of your changes; building an extension will typically increase the rebuild costs of your home if the worst was to happen therefore your insurance company may raise your premium, so you should factor this into your budget.

Hire The Right People

Hiring the right people for the build of your house extension will save you costly replacement work in the future, so you should ensure that you carefully research your local builders and check their reviews, this will ensure that your builder has a good track record and is trustworthy.

You should use a trade professional database such as CheckATrade to ensure that you are dealing with a reputable and trustworthy builder. CheckATrade scrutinises that traders pass up to 12 checks before joining the database, allowing only quality tradespeople to join their database.

Building Regulations & Planning

Permission Due to permitted development rights, you will not be required to apply for planning permission for single-story or conservatory extensions unless any of the following factors apply to you:

You live in a listed building

Your home is located in a conservation area

Your home is under a Article 4 Direction

There are certain circumstances when rear, side and front extensions require planning permission, so you should check with your Local Authority as to whether you need to apply for planning permission.

Even if you do not have to apply for planning permission, your project must meet Building Regulations, this is a legal requirement set out by the UK government.

Building regulations will cover all aspects of the extension build from external walls to floors and drainage to doors and windows. If you are carrying out building works near or on a wall shared with your neighbour, you will need a Party Wall Agreement.

You are required to inform your neighbour of any building work that you want to execute near or on your shared boundary. You must give your neighbour notice between 2 months to a year before you plan to commence building works and any agreement reached should be in writing.

You are required to pay for any building works that you start on a party wall, your neighbour is not obliged to pay just because they agreed to the works.

Lighting Your Extension

You should give careful consideration to how you will light your extension. Rooflights are ever-increasingly being used to illuminate extensions through an increase of natural daylight, alleviating the reliance on artificial lighting.

Glass rooflights are an effective way at increasing the levels of natural daylight in your extension whilst adding an aesthetic touch. An increase of natural daylight can go a long way in boosting the mood of inhabitants in addition to increasing productivity, this is why many of our clients opt to install their rooflight in a home office.

Rooflights can be incorporated to suit various applications, with many options available on the market. If you are planning to utilise your extension for a kitchen or bathroom, you may opt for an opening rooflight to subsidise the humid environments, many rooflights.com customers purchase the Glazing Vision VisionVent Rooflight as they can achieve increased levels of ventilation effortlessly at the touch of a button.

If you are planning to construct a two-storey extension with a pitched roof, you will need to install a roof window as most rooflights are designed for flat roof applications only.

There are roof window options to suit every need, from electrically opening windows to conservation windows to meet stringent planning regulations.

Do You Need An Architect?

Prior to commencing your extension build planning, some people opt to enlist the services of an architect to help them find the best solution for their individual needs. Enlisting the services of an architect may not be needed for small scale projects but it can be beneficial for larger projects as they can adapt plans to your bespoke needs, advise on building regulations and planning permission and help you manage your budget.

Appointing an architect will incur costs, so this needs to be factored into the project budget, but their advice and assistance can be invaluable especially for large scale projects.

Adding rooflights and roof windows to your extension will add an aesthetic element, allowing natural daylight to fill the space and make it more welcoming.

Our experienced team are well-versed in working with customers to choose the perfect product for their chosen application, reach out to our team today and turn your idea into a reality.

Read more

When Do You Need A FENSA Certificate?

23rd September 2024

We frequently get asked by customers if their builder will need to produce a FENSA certificate when installing our rooflights and roof windows, there seems to be confusion over what a FENSA is and its applications

Read more

Legal

Planning Permission

Roof Window

How To Pick A Rooflight

23rd September 2024

When it comes to enhancing natural daylight and ventilation in your home, rooflights and roof windows stand out as a popular choice. They are an increasingly popular solution to a lack of natural daylight, and can elevate the aesthetics of your home.

However, we understand that choosing the correct rooflight, roof lantern or roof window can be a complex task. You need to consider factors such as design, functionality and proven benefits.

Read more

DIY

Planning Permission

Rooflight

Why Builders Consider Rooflight Lead Time

23rd September 2024

Whether you’re a builder, architect or homeowner understanding lead time is crucial to a project’s success and ease

Read more

The Key Benefits Of Natural Daylight With Rooflights

23rd September 2024

Rooflights come in all shapes and sizes, providing direct views to the sky and allowing an abundance of natural daylight to flow into any room, and the benefits of natural daylight are expansive. As opposed to vertical windows which may be obstructed by outside structures, rooflights provide uniform distribution of natural daylight throughout the day as the sun moves across the sky, providing a consistent level of natural daylight at any time of the day.A recent survey found that 84% of home buyers valued the amount of natural light in a property as the most important factor in their search, so rooflights will not only increase your mood and physical health, but they will also increase the value and appeal of your home.

The Benefit Of Natural Daylight

The benefits of natural daylight are plentiful, offering numerous benefits for both individuals and the environment.

Increased exposure to natural daylight stimulates the production of Vitamin D in the body which is essential for bone health and immune function, contributing to a healthier life.

In addition to the physical health benefits, exposure to natural daylight enhances mood therefore reducing the symptoms of depression and anxiety.Natural daylight maintains the body's circadian rhythm, commonly known as the body’s internal clock, which boosts productivity and promotes better sleeping patterns.As well as the proven physical and mental benefits for individuals, the installation of rooflights to increase the levels of natural daylight will have an impact on the environment.By maximising natural daylight in your property, you rely less on artificial sources of lighting which significantly reduces your energy consumption particularly during the summer months with longer days, in turn reducing your carbon footprint.A lesser known benefit of installing the correct rooflight is lower heating costs as sunlight can provide passive heating, reducing the need for artificial heating in the winter months. Ventilation rooflights can also provide enhanced air quality and circulation in the summer months, reducing the use of fans and artificial cooling devices.

Choosing The Right Rooflight

To maximise the impact of your rooflight, you should ensure that you choose the correct rooflight for your requirements. rooflights.com sells high quality rooflights to transform your home through increased natural daylight. Flat rooflights provide a contemporary aesthetic, with many flat rooflights such as the Glazing Vision Fixed Flushglaze rooflight providing ‘frameless internal views’ providing a clear view to the outside world and allowing an abundance of natural daylight to enter the home through the sleek rooflight, adding an enhanced aesthetic appeal to the property too.Roof Lanterns are an aesthetic solution, adding a touch of elegance to certain architectural projects. Their unique design features multiple glass panels which are set at angles, allowing an increased amount of daylight to enter the space, creating a light and open space.Alternatively, Dome rooflights are unique as they are often an affordable option for many projects and are commonly used in buildings such as hospitals and schools due to their versatile uses.The rooflight that you choose should depend on your specific project requirements, the architectural style of your building and your budget.The placement of your rooflight in your property will have an impact on the amount of natural daylight that enters through the rooflight.Natural daylight can help make spaces look more inviting, it can also highlight architectural features in your property adding to an elegant aesthetic appeal.If you are installing a dome rooflight, placement is important as the incorrect placement can lead to intermittent glare.

If you are not sure which rooflight you require, or where to install it, get in touch with our experienced team on 01379 454020 or email us on info@rooflights.com

Read more

Natural Daylight

Rooflight

Do You Need Planning Permission For Rooflights?

23rd September 2024

rooflights.com customers frequently ask whether they need planning permission to install our rooflights and roof windows, and this depends on numerous factors

Read more

Planning Permission

Rooflight